Water Storage Tank for firefighting purpose

- Home

- >

- Business Description

- >

- Water Storage Tank for firefighting purpose

- >

- Construction process

Construction process

Unitary Horizontal Cylinder Type Water Storage Tank

|

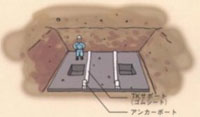

1.Installation preparations ● Construct flat foundation with concrete.(Foundation may be unnecessary depending on soil quality and groundwater level) ● Lay rubber sheet to prevent damage to tank. |

2.Delivery ● Deliver unitary tank by 10-ton truck or low-bed trailer. |

|

|

|

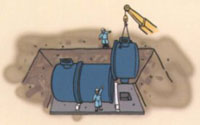

| 3.Installation ● Attach designated wire and hooks to lifting lugs on tank and suspend it. ● Crane capacity must be at least 20 tons.(Varies depending on work radius) |

4.Back filling ● Use earth and sand suited to site or soil generated from excavation or otherwise and exercise caution with back filling. ● Add water while sufficiently compacting backfill. ● Do not drive heavy machinery directly over water tank when back filling. |

|

|

|

Divided Horizontal Cylinder Type Water Storage Tank

|

1.Installation preparations ● Construct flat foundation with concrete.(Foundation may be unnecessary depending on soil quality and groundwater level) ● Lay rubber sheet to prevent damage to tank. |

2.Delivery ● Deliver unitary tank by 10-ton truck or low-bed trailer. |

|

|

|

| 3.Installation ● Attach designated wire and hooks to lifting lugs on tank and suspend it. ● Crane capacity must be at least 20 tons.(Varies depending on work radius) |

4.Assembly and installation ● Weld parts together and make solid piece with FRP on inside and outside. |

5.Back filling ● Use earth and sand suited to site or soil generated from excavation or otherwise and exercise caution with back filling. ● Add water while sufficiently compacting backfill. ● Do not drive heavy machinery directly over water tank when back filling. |

|

|

|

Caisson Method Vertical Cylinder Type, Water Storage Tank

|

1. Excavation at installation location and delivery ● Excavate burial site with excavator. ● Perform base leveling on installation surface and make it flat. ● Deliver divided tank with small truck. |

2. Suspension ● As with solid type, suspend tank from hangers. ● Crane capacity must be at least 7.5 tons. |

|

|

|

| 3. Assembly ● Weld parts together and make solid piece with FRP on inside and outside. |

4. Base/top plate installation ● After getting down to position, attach base/top plates. |

|

|

|

Copyright © 2024 TAMADA CORPORATION All Right Reserved.

Copyright © 2024 TAMADA CORPORATION All Right Reserved.No reproduction or republication without writtenglish permission.