3D Conveyor

Conveyor for food items that can convey food items while heating or cooling them. You can heat, cool down, dry, ferment, and store food items such as frozen food items and instant food prodcuts.

Features

As the conveyor is multistage (from 10 stages to 18 stages), you can install at limited space.

The compact conveyor device results in energy conservation (heat, electricity, water).

Size of carrying plates and capacity of the conveyor can be designed according to processing volume and processing time of the product work piece.

Food items can be directly heated, indirectly steam-heated, or heated with electric heater.

Chilled water Jet cooling, indirect cooling, and cold air cooling are available.

Can be embedded in freezer box cooling and freezer room.

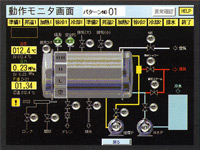

Production volume management and operational status verification is possible through conveyor monitoring system.

“Unmanned” automated processing is possible by combining with transfer equipment and/or transport conveyor.

Sen'atsu Steam Sterilizer

The compact retort pot (compact cooking sterilizer) is HACCP compliant cooking machine. “Sen'atsu Steam Cooking Sterilizer” has both boiling and retort food sterilization functions.

The longer the heating time, the quicker food gets deteriorated and less of vitamins, protein, and other nutrients. Today, people in the food industry are looking to cook which minimizes the degradation and loss of nutrients while maintaining the original taste, flavor, and freshness of food.

However, from the standpoint of food hygiene, sterilization of O157 coliform, Norovirus, and botulinum bacillus, which are resistant to heat, is required.

In order to solve this contradictory problem, there is a lot of interest in the Sen'atsu sterilization cooking method that minimizes the thermal degradation of food by consecutively performing cooking and sterilization, which were performed separately in the past, in one pressure vessel.

Features

Maintains the freshness of food for long time: Because food process under pressure can maintains freshness, the inherent taste and flavor of food can be preserved at normal temperature.

New product development and expansion of sales channels: It is highly suitable for medical and nursing facility food, hospital food, and extramural cooking because food can be cooked fresh without losing the nutrient content.

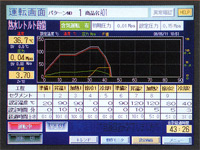

Food safety and hygiene: It is compliant to HACCP and ISO22000 and it sterilizes the food with high pressure, high temperature, and short time processing. It can fully sterilize the food by killing O157 coliform, Norovirus, and botulinum bacillus that are resistant to heat. Moreover, it can also manage and record the status of sterilization and heating.

Highly reliable cooking: It takes only 90 seconds to raise the temperature up to 100 degrees in Celcius. The range of temperature repeatability is within 1℃. The difference in temperature between the upper and lower trays is less than 1 ℃, and the same level of sterilization is possible with either tray. Pressure and temperature inside the pot are controlled optimally, and therefore retort pouches are not damaged or ruptured.

Easy and simple operation: Fully automated, anyone can operate it with simple push-button operation. 9 patterns of temperature settings can be stored, and they can be selected just bypressing a button.

Compact space design: With the most compact space design in the food machinery industry, which saves work space.

Sen'atsu Steam Sterilizer Mini

Multifunction cooking sterilizer.

HACCP compliant. High pressure and high temperature, this sterilizer allows complete sterilization in a short duration.

It is suitable for medical and nursing food, and extramural cooking because cooking can be done without losing taste and nutrients of food.

Features

Easy to use one-touch panel. 50 patterns can be registered (standard). 3000 error items can be saved as history. 100 data items can be stored and managed.

Three types of sterilization function get into one machine. (shower recirculation type, full water recirculation type, and steam-heating type)

Rotating Steam Cooker

It is used by the customers of Natto (fermented soya beans) industry, and it is made of all stainless steel and it is available in150kg, 180kg and 240kg capacity.

Features

By adding options, we can also make 360-degree rotating steam cooker.

Temperature can be controlled by a recorder attached.

Temperature and valve control can be set up to allow cooking steps and patterns.